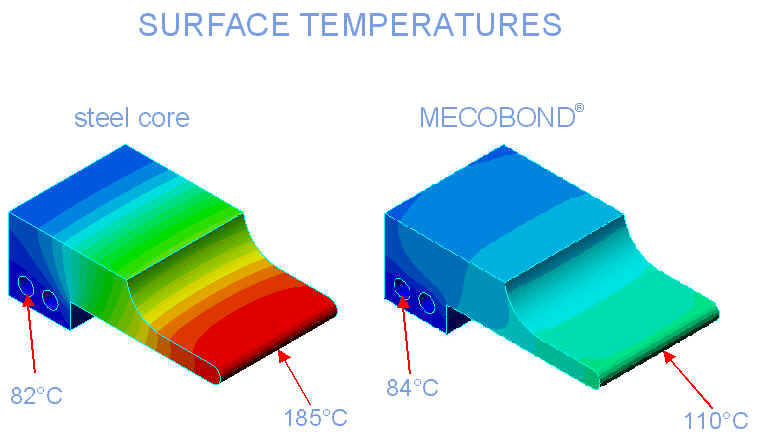

The Principle

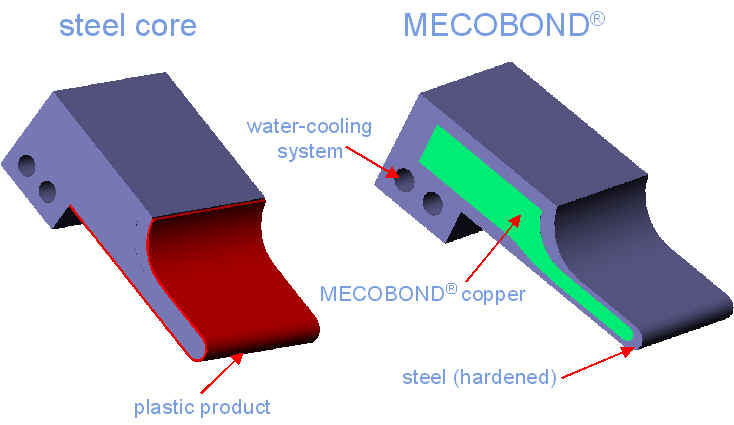

The principle of MECOBOND® (Mold

Equipment Composite Bond) is based on the use of solid-body heat conduction in

a spatial compound of steel and copper materials.

The steel forms the mantle of the mold core

including the entire surface forming the contour, thereby ensuring protection

against wear and mechanical stability.

The copper is located in the interior of the

mold core and carries out the actual dissipation of heat. The copper and steel

are diffusively bonded with one another.

The result of this task sharing by the two

different materials is a

"steel core which conducts heat like copper."

Example for cores shown above: